Table of Contents

Introduction

When a manufacturing employee quits, what does the company lose? The amount of work one individual can output, certainly, and any tribal knowledge that person had accumulated is lost as well. Add the resources it takes to find, vet, and hire a replacement to the list of losses that come when a familiar face is replaced by a strange one. The list goes on, but the point is clear: turnover comes at a high cost, especially in the manufacturing industry.

By some estimates, the financial drain of turnover suffered by employers in the manufacturing industry adds up to hundreds of thousands, if not millions, of dollars each year. Training typically can cost upwards of $3,000 per hire and an additional $1,500 per employee per year.

The manufacturing industry is plagued by one of the highest rates of any U.S. industry: a recent report found that two in five manufacturing companies have a turnover rate of over 20%.

The need to address this issue becomes even more pressing when considered in context of the current labor shortage in manufacturing. For years, U.S. manufacturing companies have suffered from the country’s shortage of skilled labor, and the skills gap is only widening. By 2028, it’s estimated that 2.5 million manufacturing jobs will go unfilled. The problem stems in part from the coinciding retirement of Baby Boomers and relative lack of enthusiasm towards skilled-labor jobs from younger generations.

Employers in the manufacturing industry must understand that they’re fighting an extremely competitive war for talent. One of the best ways to win it is by holding on to the employees they already have.

Retaining employees helps manufacturing companies mitigate costs that come with turnover and as an added benefit, employees with longer tenure tend to do better work. Long-term employees know all the trade secrets and have a more holistic understanding of why your manufacturing company does things the way it does. There’s no substitute for the level of skill that comes with years of repetition and practice.

All of this is to say that if your company doesn’t have strategies in place to fight turnover, it will suffer a variety of consequences — from hiring costs to a less skilled labor force — until it does.

What makes employees leave?

Before we delve into ways employers in the manufacturing industry can drive turnover down, let’s establish a baseline understanding for why employees leave in the first place. While details may vary, the scenario is usually one of two types: either the employee is actively dissatisfied or they are complacent but feel better opportunities may lie elsewhere.

We’ll start with the latter, which is less complicated than the former. When employees feel there is nothing unique about the employee experience at your particular organization, eyes tend to wander. If nothing else, there’s appeal in the novelty of a position at a new company. On top of that, they may feel optimistic about new employers offering a better-than-average employee experience.

There are a variety of ways employers in the manufacturing industry can create remarkable, distinctive employee experiences. Depending on the depth of your company’s resources and the temperature of its existing culture, some options will make more sense than others. Later on this eBook, we’ll share several suggestions for building culture and developing an employee experience that rivals that of other manufacturing companies.

We’ll also share actionable insights that can help employers tackle the other scenario: when employees are actively dissatisfied. In these cases, turnover is a consequence of a toxic work environment. To drive down turnover, employers need to address the toxic factors (whatever they may be) directly.

Workplaces can be toxic in a lot of different ways.

In the manufacturing industry, employees sometimes face work environments that are literally toxic. If employees at your company have to suffer through unsafe or otherwise physically detrimental working conditions, know that you are actively driving them away — and also likely violating legal safety standards.

Even when a work environment is physically fine, cultural factors can be another cause of a toxic work environment. Whether it’s micromanagement, hostile peers, or a generally negative group mindset, leaders looking to reduce turnover at manufacturing companies should also keep an eye out for interpersonal circumstances that might push employees away.

Removing toxic factors from your work environment is an essential first step in the fight against turnover. Before you take any strides to create an ‘above and beyond’ employee experience, be sure that these circumstances have been addressed.

4 Ways Manufacturing Companies Can Fight Turnover

If you want to keep your manufacturing company far, far away from the industry average for turnover, you’ll need a strategy that incorporates both preventative and proactive measures.

As stated in the previous section, the first step in any successful fight against turnover is to eradicate malignant factors that may be negatively impacting your work environment. Do not ask employees to compromise on safety standards. Do not ask them to tolerate disrespectful peers. Do not ask them to put up with managers who lack professionalism.

Simply, do not ask employees to persevere in a work environment that has any trace of toxicity, physical or otherwise.

With these baseline standards in place, you can begin to establish meaningful cultural norms that make your workplace “sticky” to existing talent, and magnetic to prospective talent. Your on-the-floor manufacturing employees are the backbone of quality. By improving their employee experience and lengthening their tenure, you strengthen your entire organization. When implemented correctly, the four measures recommended below can bring revolutionary changes to your company.

1. Maintain a Safe Work Environment

To understand the importance of creating a safe working environment, let’s first explore Maslow’s Hierarchy of Needs, an important psychological concept.

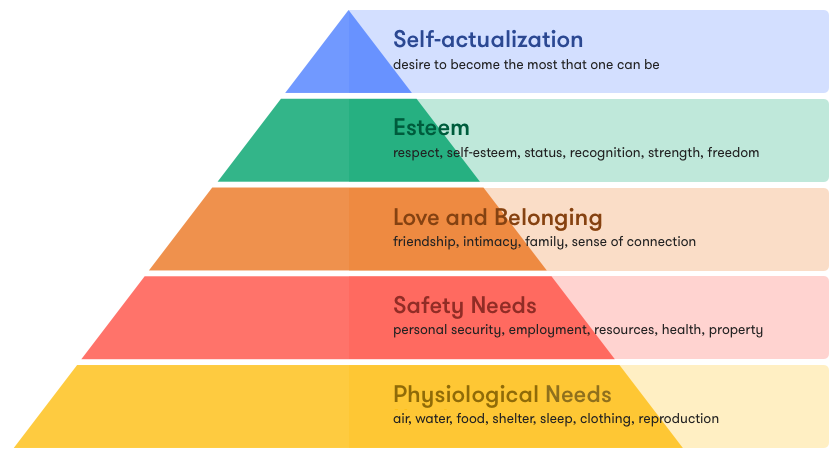

At a high level, this psychological model essentially states that all people have a series of successive needs. The most basic needs are physical, followed by a need for safety, belongingness, esteem, and lastly self-actualization. According to Maslow, who developed the theory, these needs must be fulfilled one at a time, in order. Unmet needs are motivators. Once a need has been fulfilled, it ceases to be motivating and the individual progresses to the next tier of the pyramid.

Here’s the important takeaway for someone looking to drive down turnover at a manufacturing company: physical and safety needs come first.

These fundamental needs represent the ‘base’ of the metaphorical pyramid. Employers that ask manufacturers to compromise on physical/safety standards will hardly be able to devote attention to higher-level needs like esteem and self-actualization. Someone focused only on keeping themselves physically out of harm’s way is unlikely to be happy; they have few if any cognitive resources available to devote to achieving an optimal mental state. An employee in this position will understandably be interested in alternative employment options, where they wouldn’t have to be so preoccupied with meeting their own baseline needs.

In an industry with an estimated labor shortage of 2.5 million employees, it’s a fair bet that anyone looking for a new job is going to find one — so don’t encourage your employees to go looking.

While this all makes sense in theory, in practice maintaining a safe work environment means managing many moving parts that require constant upkeep. Here are a few strategies you might consider to make sure that your work environment upholds top-notch physical safety standards:

Automate Safety Procedures

We’re living in 2020. Wherever you can outsource manual upkeep of safety standards to automation, you should. Not only does this minimize the amount of time and resources that actual employees have to devote to keeping the workplace safe, algorithms and software are a lot less prone to variable mistakes than humans.

Employers in the manufacturing industry face a seemingly never-ending list of safety procedures to stay on top of. Many leaders have found success using continuous improvement software to keep up. This software helps managers easily ensure that all employees have completed proper safety training, and makes it simple to identify and follow up with employees who have not. Additionally, this kind of software allows managers and employees alike to track safety checklists in a centralized location.

These processes all revolve around the same goal: keep safety standards high and employees informed and compliant. When the processes that support these goals are automated, it’s a lot easier to maintain the kind of work environment you need to prevent turnover.

Make It Easy to Report Problems

For all the good that comes with automation, accidents still happen, machines still break, and processes don’t always unfold as planned. As a leader in the manufacturing industry, you will inevitably have to deal with unexpected safety concerns. Be realistic about the fact that you can’t automate all of these processes away. Instead, focus on making sure you and your team are notified as soon as any issues come up. If you don’t know that a problem exists, how are you going to fix it?

Think through how easy it is to report a problem from the perspective of one of your on-the-floor manufacturing workers. Toyota famously created the “Andon” cord that made it easy for workers to stop the line and report an issue. Do your employees have easy access to managers and supervisors? Is there a centralized location where safety concerns are documented and tracked? Or do requests swirl around in a void where they might be addressed or forgotten until the situation becomes an emergency? As anyone can imagine, the latter is far from ideal.

Respond Quickly

This last suggestion goes hand in hand with the preceding one. If employees don’t have an easy way to report problems, the recommendation to respond quickly becomes irrelevant. Employee safety should be your highest priority, and the moment you find out it’s been compromised, you should respond.

If this doesn’t happen, it’s rarely because the manager simply won’t care to address the issue. More often, they forget or are never alerted to the problem in the first place. Once again, software that enables centralized tracking systems and well-established workflows can help sidestep this scenario. Use these systems to keep track of when issues arise and hold people accountable for resolving problems in a timely manner.

Until these baseline safety standards are met, it’s not time to talk about higher-level ways to make your employee experience stand out. But once they are, you can start thinking more holistically about the work environment environment at your manufacturing company — meaning physical standards, but also the quality of relationships, culture, and more. Our next point pivots towards that.

2. Practice Regular Recognition

In recent years, leaders of online workforces have turned to employee recognition programs as a strategy to keep their teams engaged. In the most successful cases, they’ve revolutionized company culture completely through these efforts.

Employee recognition programs allow team members to call one another out for success, which builds camaraderie among peers, a feeling of being seen and appreciated for hard work, and insight into one’s own strengths. Managers of online workforces who once struggled to keep their teams united and engaged have found solace in this solution.

Unfortunately, in the deskless workforce, employee recognition programs are far from being a cultural norm — yet.

Make Recognition Accessible to Everyone

The manufacturing industry’s slow adoption of employee recognition is due in large part to a misconception that these programs must be accessed online. Leaders mistakenly believe that on-the-floor workers couldn’t access the program’s social feed, where praise is shared publicly, until after the work day is done. After-the-fact recognition is a lot less valuable than in-the-moment recognition, so if this were true, it would be a problem.

Thankfully, mobile apps mean that anyone with a smartphone can participate in sending and receiving recognition. Leaders at manufacturing companies oversee many employees that don’t sit in front of a computer all day — but you can bet those employees still keep their mobile devices glued to them. Modern employee recognition software also includes a mobile app, which means employees can check the social feed as easily as they could read texts or quickly refresh an Instagram timeline. Delivering recognition is just as easy — just whip out the phones, type a quick note of appreciation, and move along. The whole process takes seconds, not minutes.

Inclusive employee recognition programs bring numerous benefits: a public recognition feed allows peers who don’t work alongside one another every day to gain insight into the great things their colleagues in other departments are doing. It also sends the message that employees in all roles and at all levels are valued and deserving of recognition. Finally, inclusive employee recognition improves the quality of relationships between peers (we’ll discuss this a little bit more in point three).

Best Practices for Recognition Programs

If you don’t have experience setting up an employee recognition program, fret not. The practice is not rocket science, and knowing just a few best practices can help you make recognition meaningful. Here are three recommendations that you should keep in mind:

Set Up Custom Recognition Occasions

If you don’t know how to use an employee recognition program, it’s likely your manufacturing employees don’t either. One of the biggest barriers to use can be uncertainty around what kinds of behaviors are ‘deserving’ of recognition through the program.

When you introduce employees to the concept of company-wide recognition, be clear about what behaviors that should be recognized. Many organizations opt to reinforce company core values, or progress towards long-term goals. Ideally, you’ll use a recognition platform that lets you set custom recognition occasions. This feature makes it so when a team member goes to send recognition to a colleague, they have specific reasons to recognize recommended by management laid out in front of them.

An added bonus to setting custom recognition occasions is that you get to capitalize on the law of positive reinforcement. There’s a lot of science to unpack there, but at its core, the law states that behavior that is rewarded will be repeated. By establishing custom recognition occasions, you control what behaviors are recognized and ultimately repeated.

Use Rewards for Added Impact

Without a doubt, recognition on its own carries weighty social and emotional value. The feeling of knowing that your peers or managers see and appreciate your hard work is incredible. That said, some displays of excellence are so above-and-beyond that they warrant more than just words to commemorate them.

To make your program maximally impactful, opt for a program that allows employees to attach points to recognition. These points can be redeemed for rewards of the employee’s choosing, which makes for a personal, memorable moment.

Not every instance of recognition needs to be accompanied by points, but for more momentous occasions (like a major accomplishment or career milestone), it’s great to have variability in the scale of recognition employees can give so achievements can be celebrated accordingly.

Pay Attention to Analytics

Managers of the most successful employee recognition programs have long evolved past the days of using recognition as merely a feel-good strategy. The right recognition provider will give you clear back-end analytics about the frequency of recognition, patterns in who is recognizing who, manager participation, and more. These analytics can help identify patterns and weak spots and give leaders a chance to intervene before they turn into bigger issues.

For example, maybe you oversee one manager who almost never recognizes their direct reports. If you can identify that pattern early, you have a chance to communicate with the individual about how recognition is an efficient way to keep their team members satisfied and engaged. Employee recognition analytics can also help make predictions about turnover, provide insights to inform promotions, and shed light on many other important cultural factors.

The benefits of regular employee recognition on morale are great on their own, but when leaders develop highly strategic programs, they reap benefits of a much greater scope than many people realize.

3. Build Peer-to-Peer Relationships

We alluded to this earlier on, but if you can make meaningful relationships a pillar of your company culture, you will almost create a work environment that encourages people to stay. Human beings are social creatures. We want people to tell funny stories to or to commiserate with when things are tough. To thrive, we need to know we’re surrounded by individuals committed to our success and continual development. This is as true at work as it is anywhere else.

Unfortunately, many people still underestimate the value of workplace relationships. Among other things, the value of strong peer-to-peer relationships includes:

- Higher employee engagement

- Lower absenteeism

- Increased productivity

- Greater employee satisfaction

- Better health outcomes

- More innovation

- Clearer communication

- Deeper trust

- Improved collaboration

- Higher motivation

It doesn’t take a lot of imagination to see how these things translate into reduced turnover. They all contribute to a cultural climate in which employees feel enabled to become their best selves. Here are a few things manufacturing leaders can do to cultivate and support these all-important relationships:

Enable Peer-to-Peer Recognition

If you do set up a recognition program, be sure to enable peer-to-peer recognition as well as manager-to-peer. It’s important for employees to know that managers see their hard work, but it might be even more important for them to know their peers see it. Peers are the ones employees actually collaborate with on a daily basis.

Build Bonds off the Clock

Support “off the clock” bonding. Regardless of how sociable someone is, when they’re at work, they’re at work. Peer-to-peer relationships may build gradually from small talk accumulated over time, but you shouldn’t wait for that to happen. Opportunities to socialize outside of work can help colleagues form meaningful connections, which in turn makes the workplace a more collaborative (and therefore productive) environment. Try to carve out time for people who work together to connect in ways that have nothing to do with work, whether that’s a company picnic, games, or another kind of team bonding exercise.

Identify Mentors

One of the best things about working at a larger company is the diversity of backgrounds, experience, and collective knowledge contained within the workforce. Encourage managers to check in with their employees about long-term goals and then see if there are more senior employees at the company who have relevant experiences or insight. Setting up mentor-mentee relationships is an extremely powerful way to support career development, which brings us to our fourth and final point …

4. Support Career Growth

The fourth and final recommendation ties back to one of the most common culprits of turnover: employees lack a sense of direction. Understandably, it’s hard to feel engaged at work when it seems like you do nothing but the same repetitive tasks everyday. When employees feel like they have access to successive opportunities for professional development, it’s much easier to stay engaged.

Use Skills Management Software

The first step in effectively supporting professional development is understanding what employees do and don’t know how to do. For managers who oversee a very large workforce, this can be daunting — but with the right tools it doesn’t have to be.

Skills management begins with a comprehensive review of all the skills employees at your manufacturing organization could have. Once you’ve compiled a list, identify which employees have which skills. Then centralize your tracking for who knows how to do what to keep your life simple.

Having a skills management system in place offers a couple of benefits. For one, it makes it easier to know who can do what jobs. This makes processes more efficient and helps avoid the frustration that comes when you ask employees to do a job that they don’t know how to do.

Skills management can also make it easier to create a clear path for professional growth. Maybe today, one of your employees has one-third of all the skills listed in your skills management software, but they’ve expressed interest in picking up a couple more. Leverage skills management to ensure your employees are continually developing their skills and progressing professionally. They’ll become stronger employees who can serve your company better.

Encourage Managers to Check-In About Long-Term Goals

The skills management recommendation is only one part of the larger practice of creating long-term career development plans for employees.

Managers should start by checking in about employees’ long term goals. Do they want to develop more manual labor skills? Would they eventually like to progress into an off-the-floor management role? Regardless of what specific long-term goals the employee brings up, having a destination in mind makes it easier to create a path to get there. Additionally, having a goal improves motivation — you’re not just at work to check boxes that day, you’re there to move your career forward and work towards long-term success.

Encourage managers to discuss long-term goals with every employee they supervise and lay out a step-by-step plan of how to get there. From there, managers should check in periodically with employees to see if they’re on track, whether their goals have changed, and if there is anything the manager can do to support that employee’s professional growth. Career development check-ins should happen at least once a quarter, if not more frequently.

Offer Opportunities for Professional Development

Take as much leg work out of the professional development process as you can. When all employees have to do is register for a course and show up, they’re a lot more likely to seize professional development opportunities. If you aren’t able to offer on-site skills development courses, consider funding or even incentivizing employees who seek and complete outside professional development courses.

In addition to making professional development more logistically feasible, managers can support employee growth by making specific recommendations about what courses might be helpful. Employees are more likely to pursue professional development when managers make specific recommendations about how to do it. Share this with managers at your company and encourage them to make recommendations accordingly.

Keep in mind that when you invest in professional development, you’re not just investing in the growth of that specific employee — you’re also improving the level of talent present in your existing workforce. It’s one of the best win-win situations in management.

Improve Retention, Improve Your Company

As you move forward with these recommendations, keep in mind that your efforts will be more successful with the right technology at your side. Not all manufacturing leaders realize how many of these recommendations can be accomplished fairly easily with modern software. Throughout this eBook, we’ve noted ways manufacturing leaders can automate or streamline these recommendations with technology. Look for opportunities to do so as often as possible. With the right tools at your side, creating a remarkable employee experience is more feasible than ever.

In an industry where the competition for talent is fierce, driving down turnover is one of the most effective ways for your manufacturing company to secure a competitive advantage. When employees stay long term, they improve their skills, which improves the quality of your product too. When you win the battle for top talent, your company is in a much better strategic position to win all other competitive wars, too.

Reward Gateway has acquired Fond!

Schedule a demo to learn how Reward Gateway can help you: